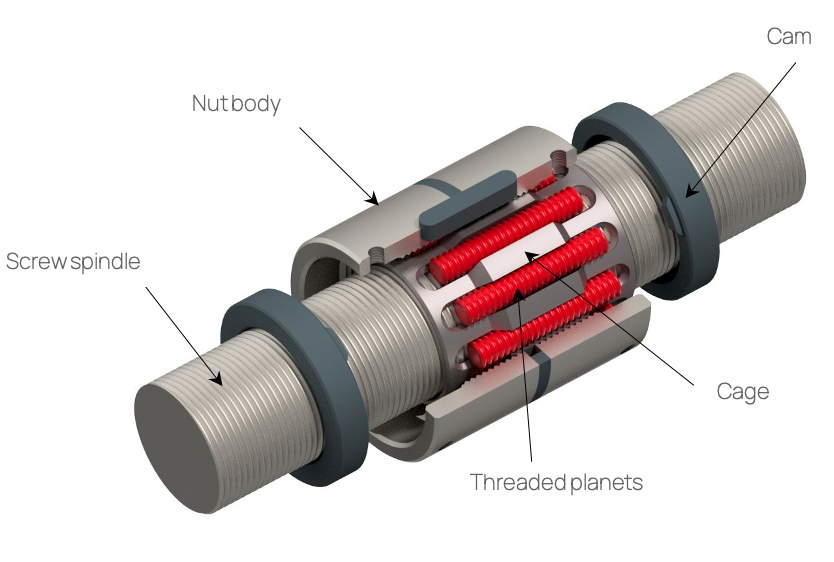

Planetary roller screws are a particularly precise and robust form of linear drive. Their construction design produces significantly higher load capacities and rigidity compared to other linear drives, such as ball screws (KGT). This is a direct result of the so-called threaded planets used in the design. The threaded planets serve as rolling elements between the threaded spindle and the threaded nut. Another great advantage of planetary roller screws is the wide range of possible leads they offer. The multi-start thread profile of the planetary roller screws allows total spindle leads of 0.5 mm to 50 mm.

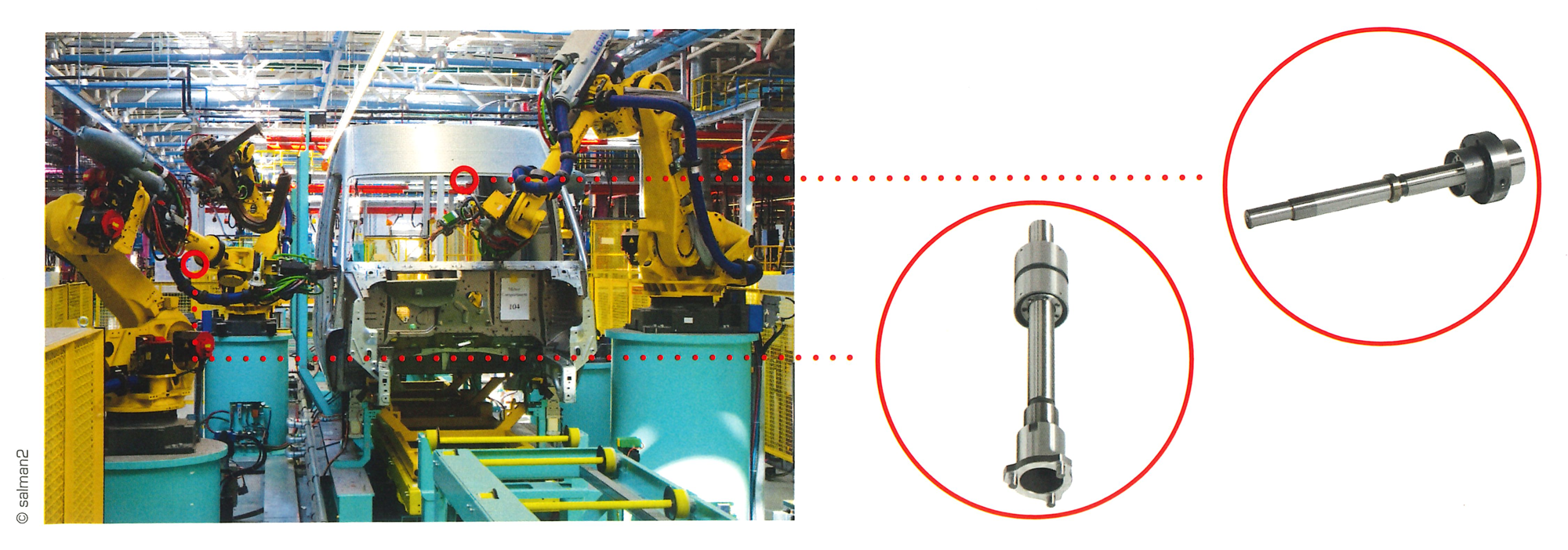

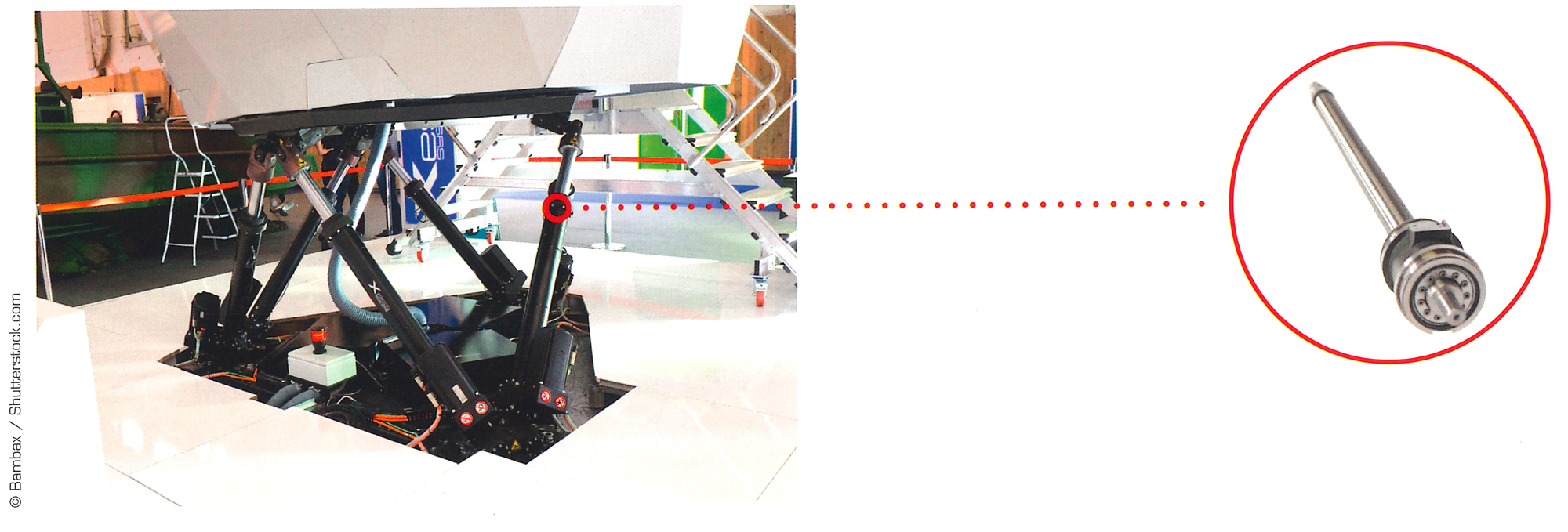

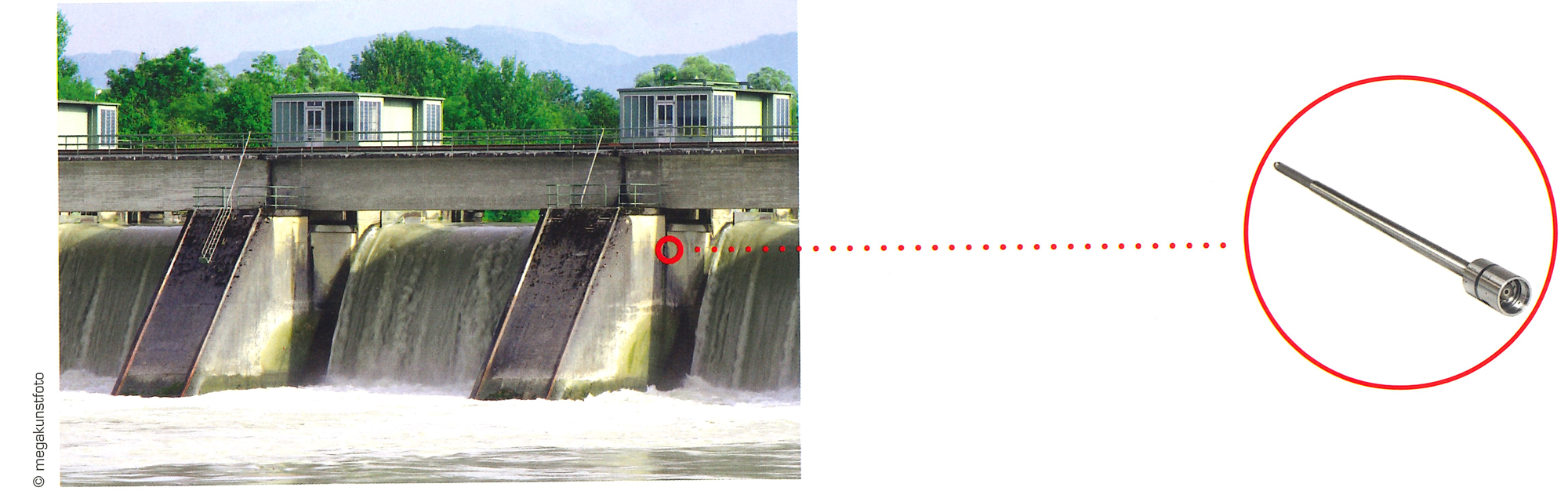

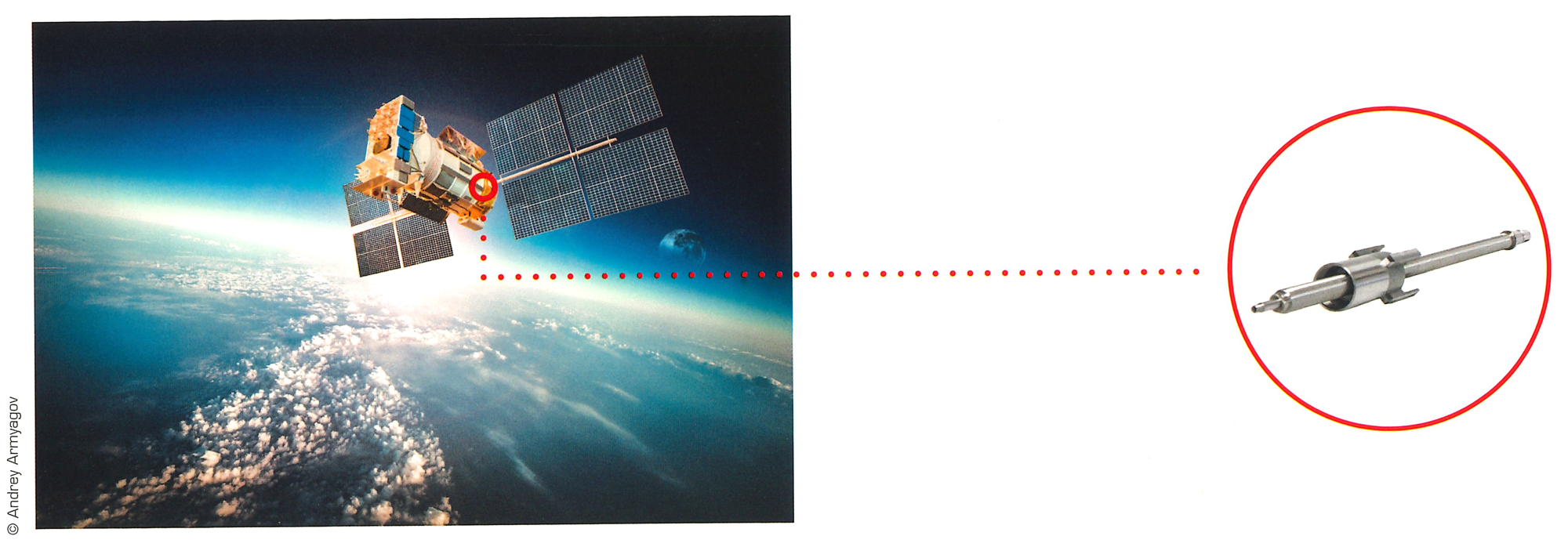

Application fields

Designs

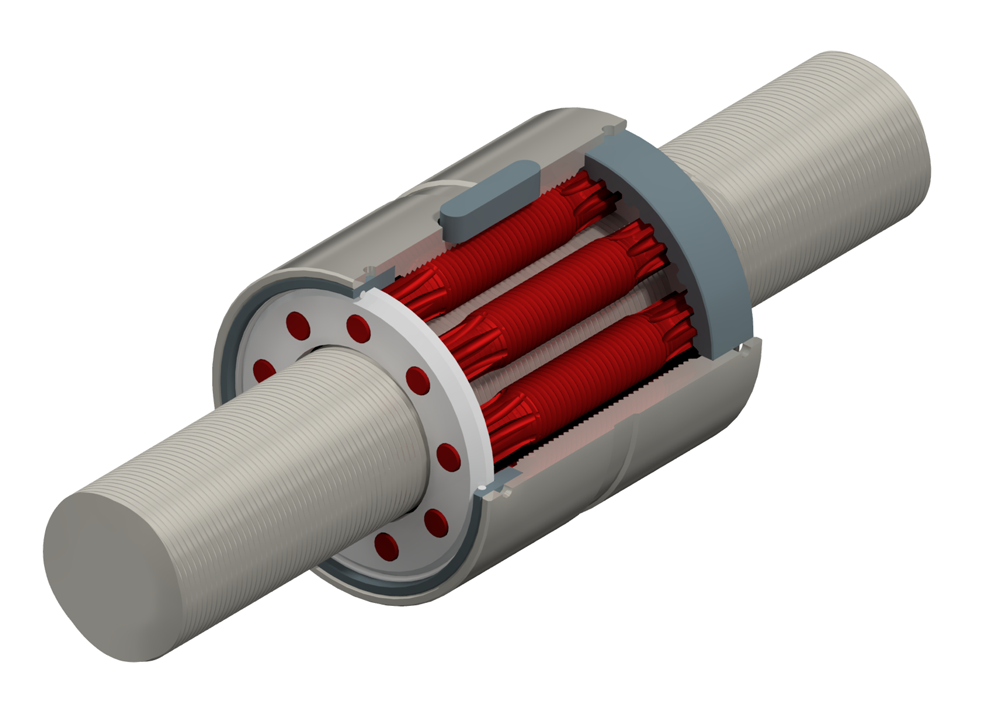

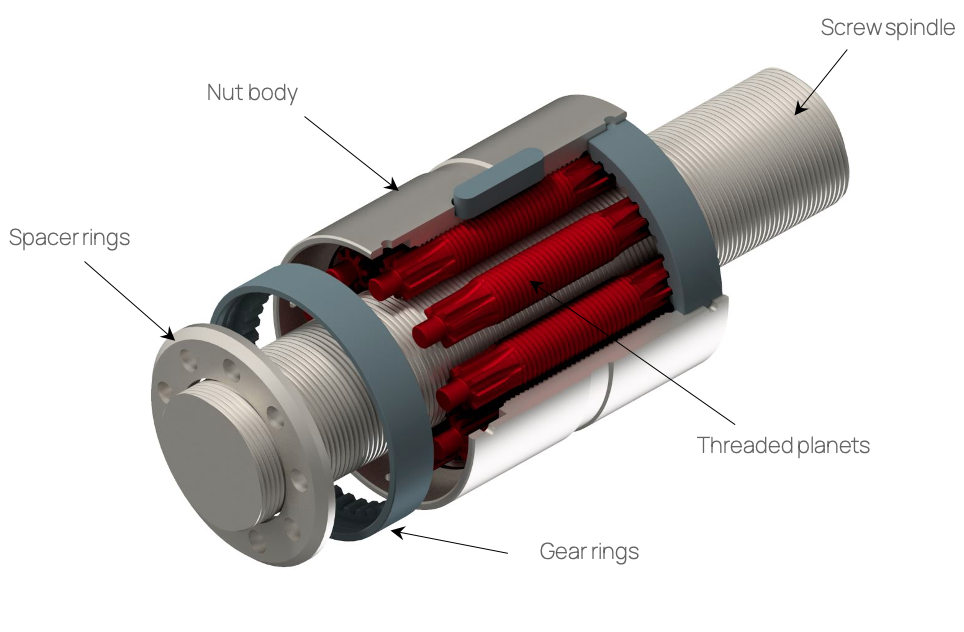

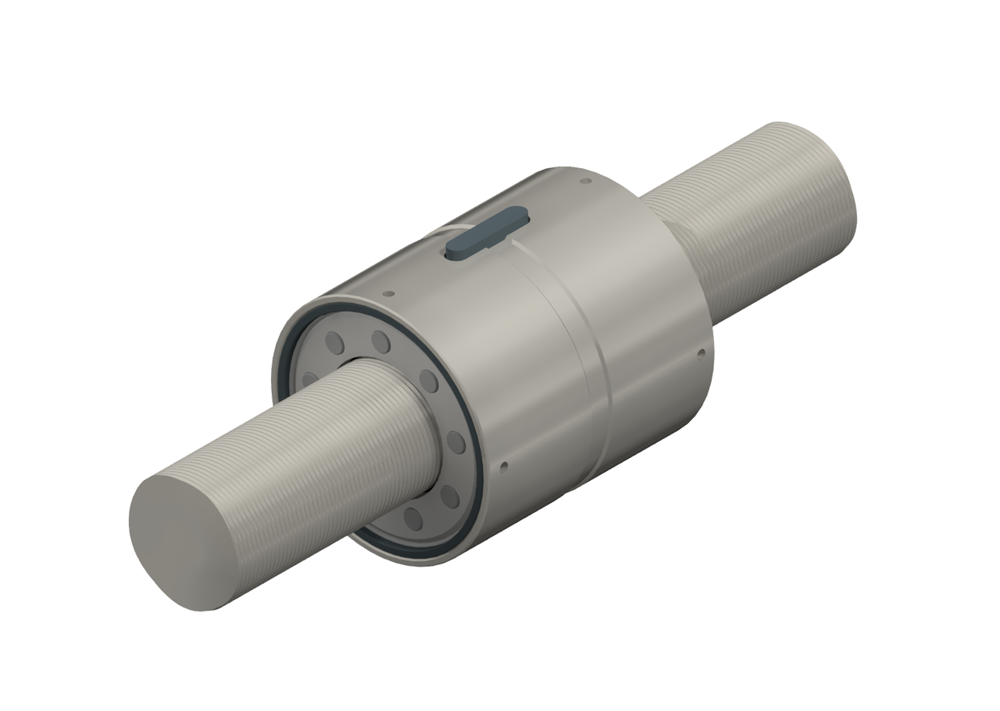

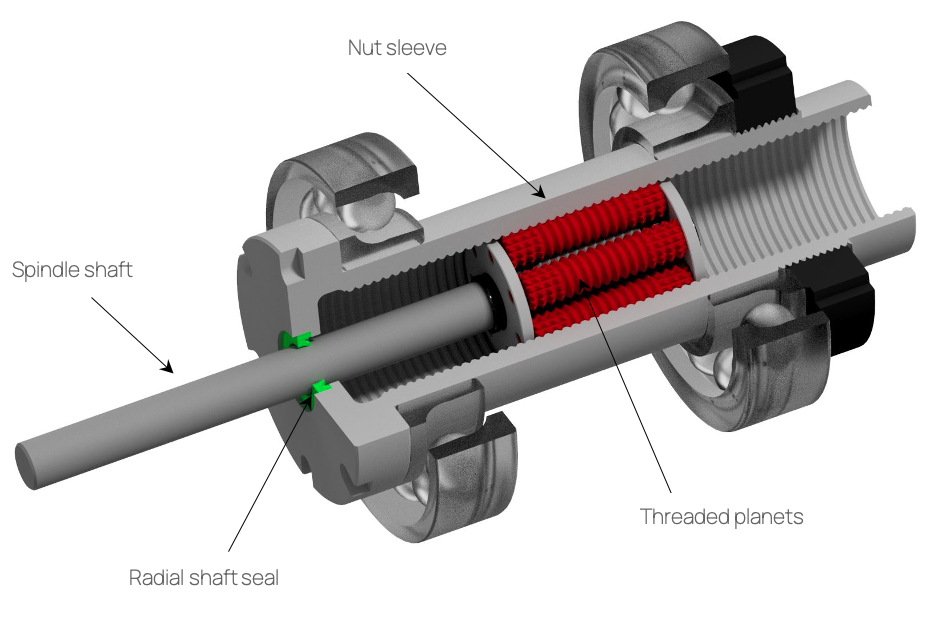

RGT: Planetary Roller Screw

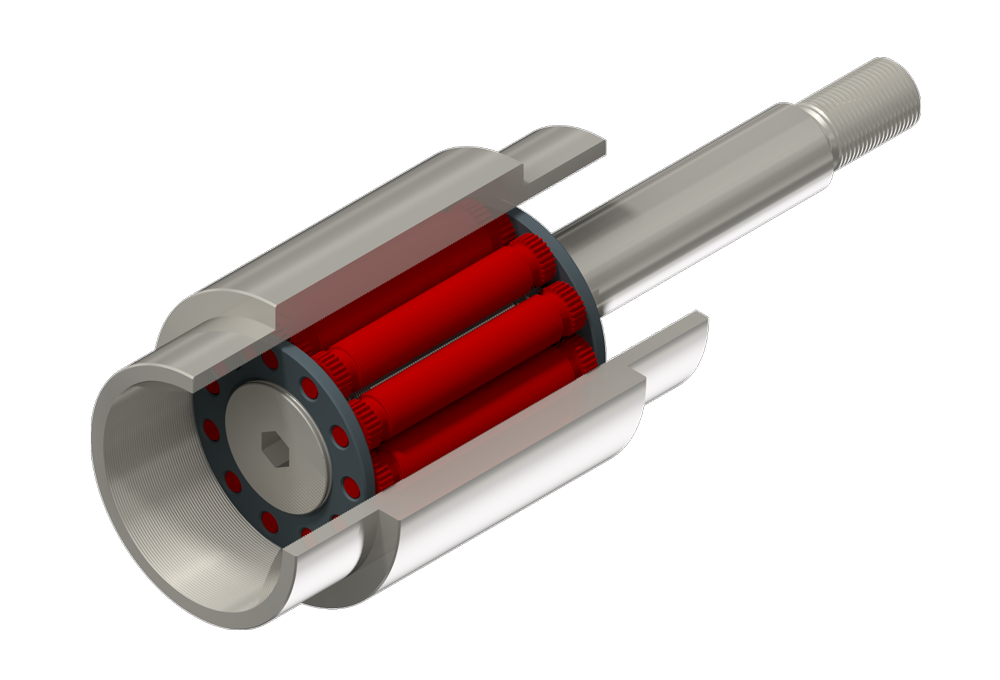

The RGT planetary roller screw consists of the following components: threaded planets, thread rolls, threaded nut, spacer rings and gear rings. The axial load is transmitted by the threaded spindle via the threaded planets into the threaded nut. The system is synchronized through gears on the planets and via two gear rings. The spacer rings, similar to the cage in a needle bearing, ensure the distance between the thread rolls on the circumference of the threaded spindle.

Spindle nominal Ø: 5 mm to 245 mm

Total spindle length: up to 10 m max.

Leads: 1 mm to 50 mm

Dynamic load ratings: up to Cdyn 5,800 kN

Static load ratings: up to Cstat 40,000 kN

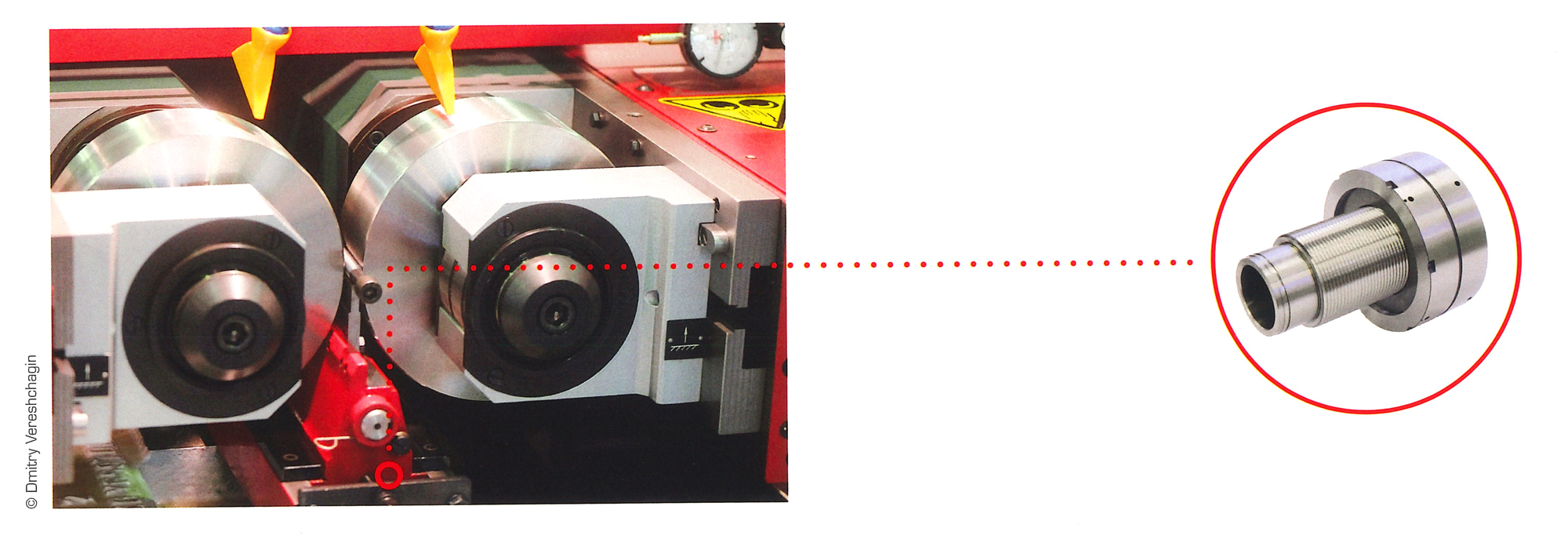

Planetary roller screws are basically used wherever an electromechanical linear drive with high precision, accurate repeatability and high load capacity is required.

The field of application mainly includes:

- Axle drives in machine tools

- Servo press drives

- Robotics applications

- Lock and bridge drives

- Automation applications in metering and joining technology for the automotive industry

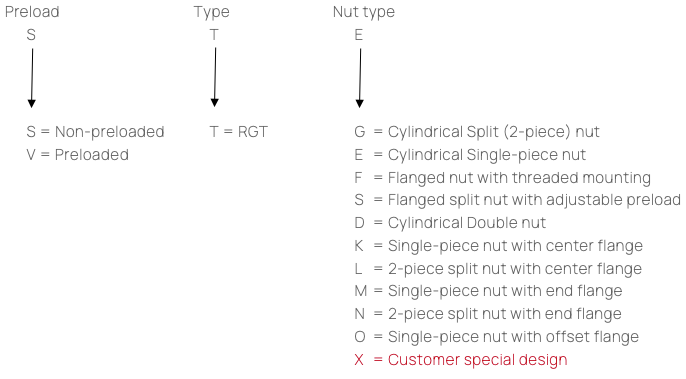

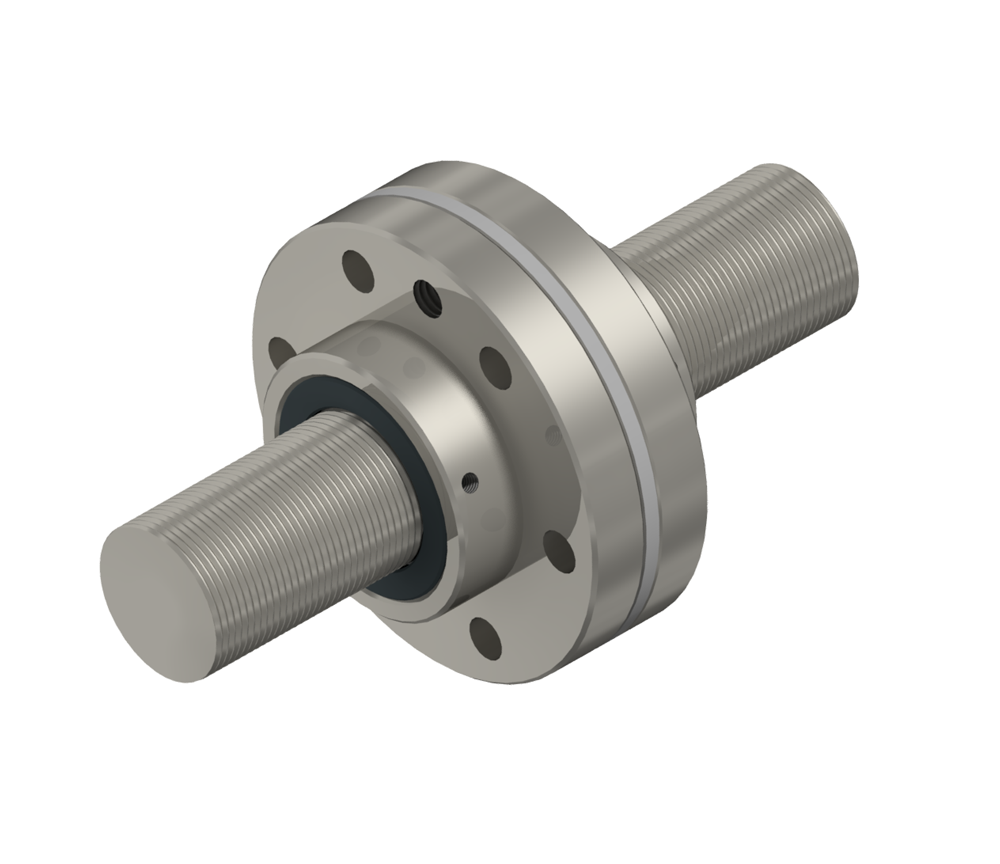

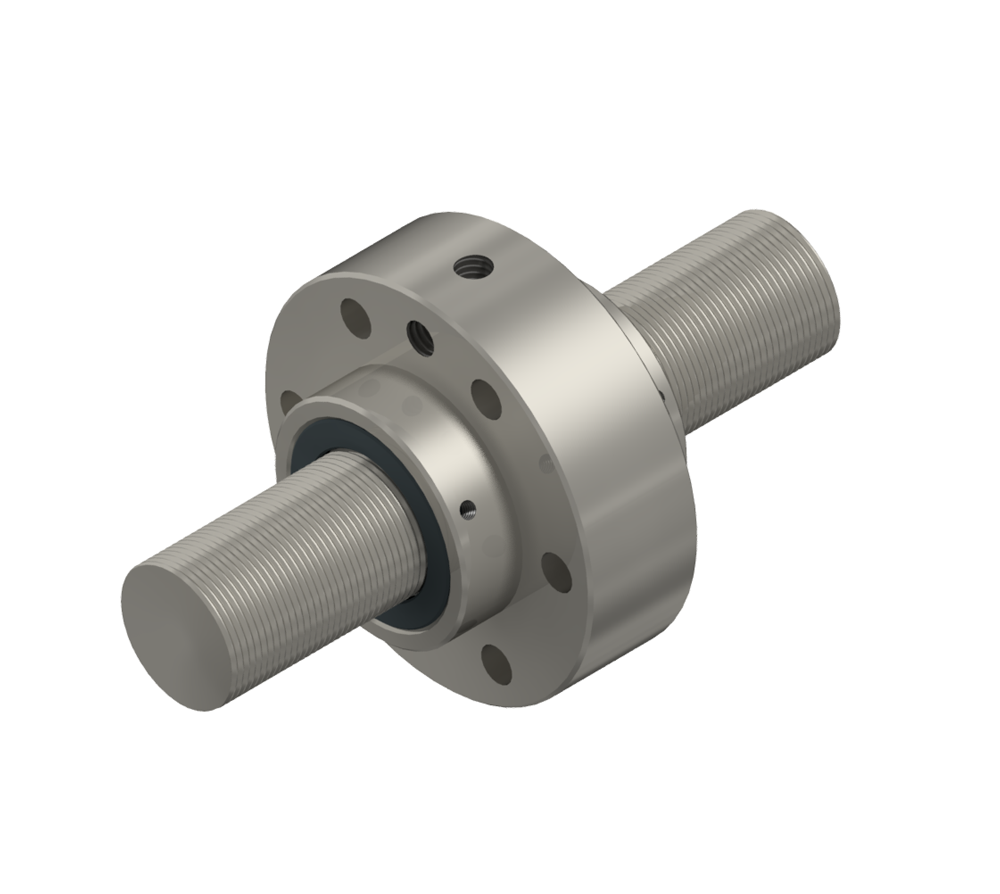

Various nut designs with different mounting options are available. If preloading of the planetary roller screws is desired, it can be achieved with so-called single-piece ground-to-fit or two-piece nut halves that are preloaded against each other. This is the reason for the subdivision of the nuts into so-called "preloaded" and "non-preloaded" in the nuts product key.

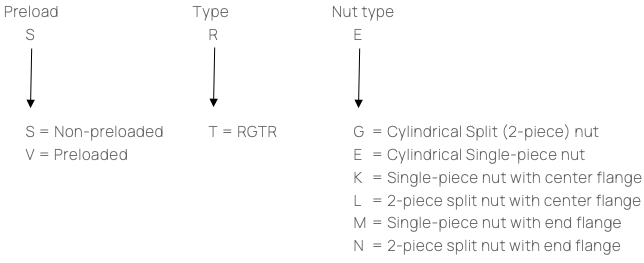

Product key

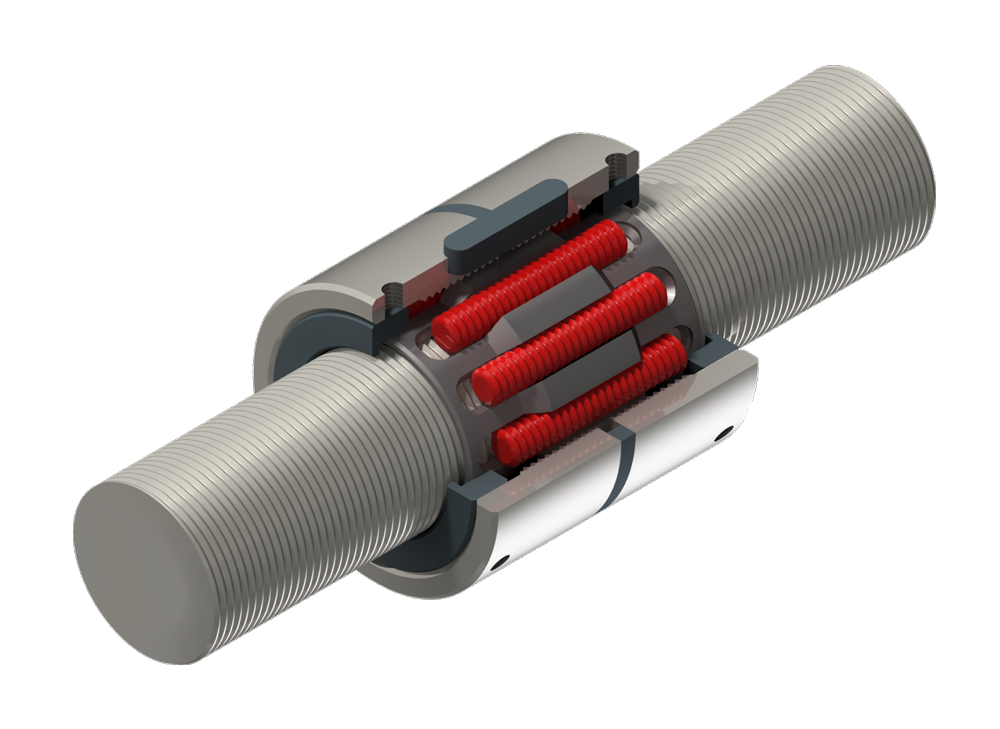

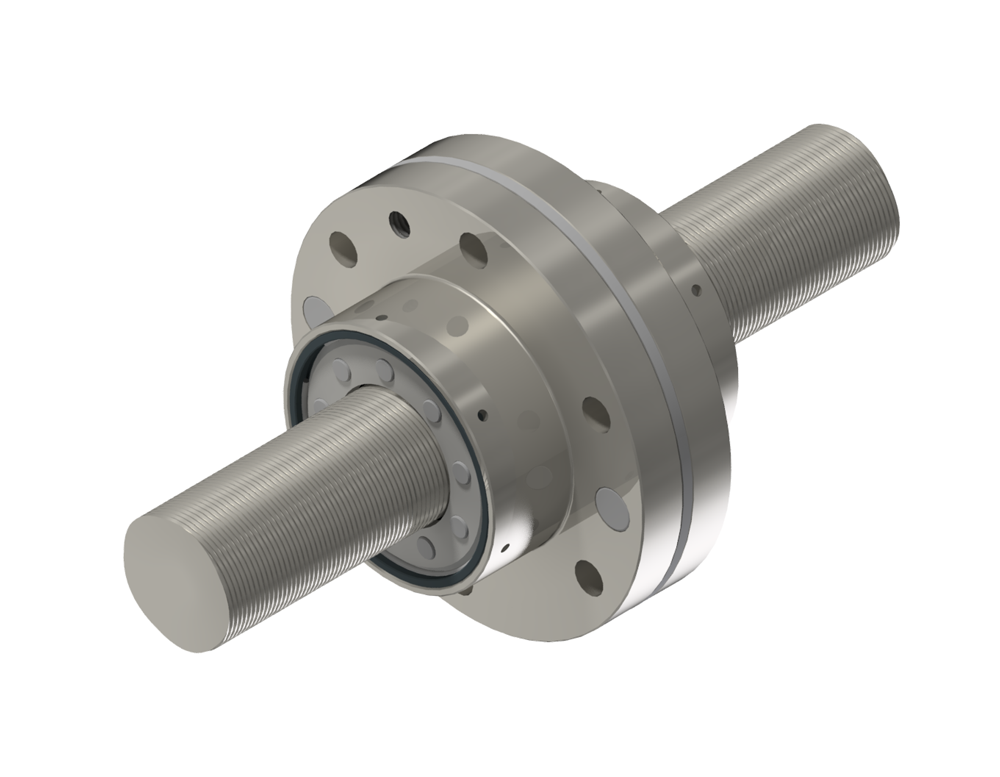

RGTR: Recirculating Planetary Roller Screw

Spindle nominal Ø: 8 mm to 125 mm

Total spindle length: up to 10 m max.

Leads: 0.5 mm to 5 mm

Dynamic load ratings: up to Cdyn 800 kN

Static load ratings: up to Cstat 3,400 kN

Recurculating planetary roller screws are basically used wherever an electromechanical linear drive with high precision, repeatability and high load capacity with a small lead is required. The small leadscrew leads allow for very high positioning accuracy under the effect of comparatively high loads.

The field of application of the RGTR includes e.g.:

- High-precision positioning applications of optical instruments in space and aerospace technology

- Valve control technology in the oil industry

- Hexapod robot drives and kinematics

Various threaded nut designs are available with different mounting options. If preloading of the planetary roller screws is desired, it can be achieved with single-piece ground-to-fit or two-piece nut halves that are preloaded against each other. This is the reason for the subdivision of the threaded nuts into so-called "preloaded" and "non-preloaded" in the threaded nuts product key.

Product key

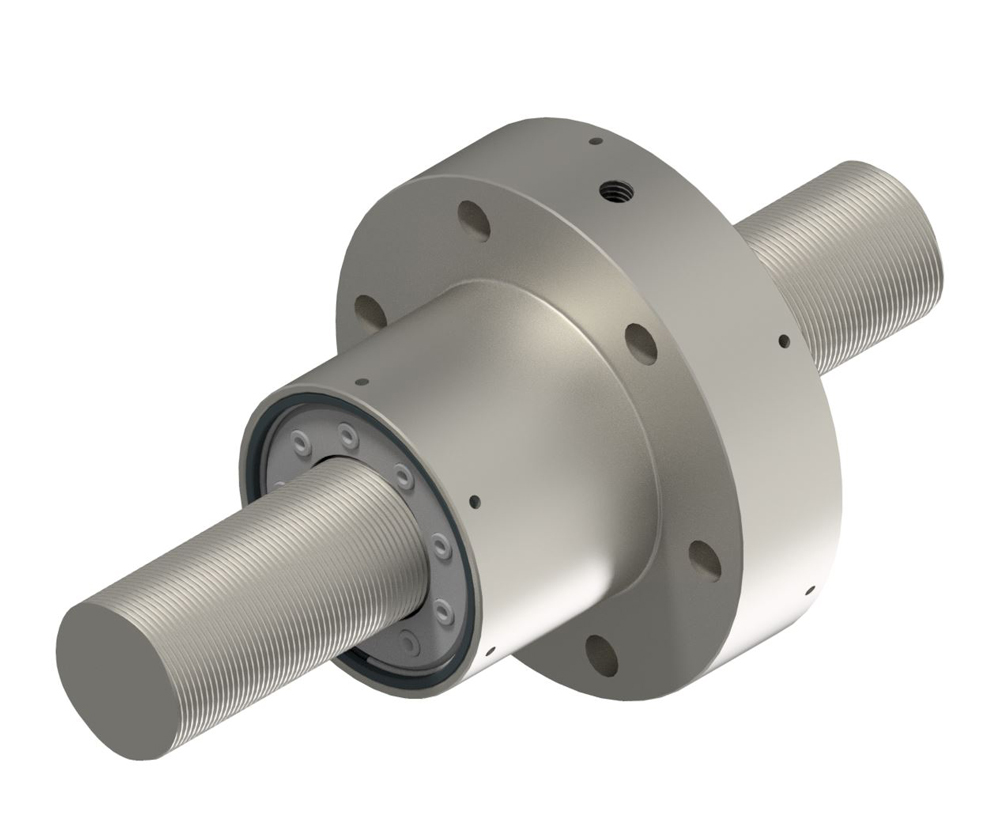

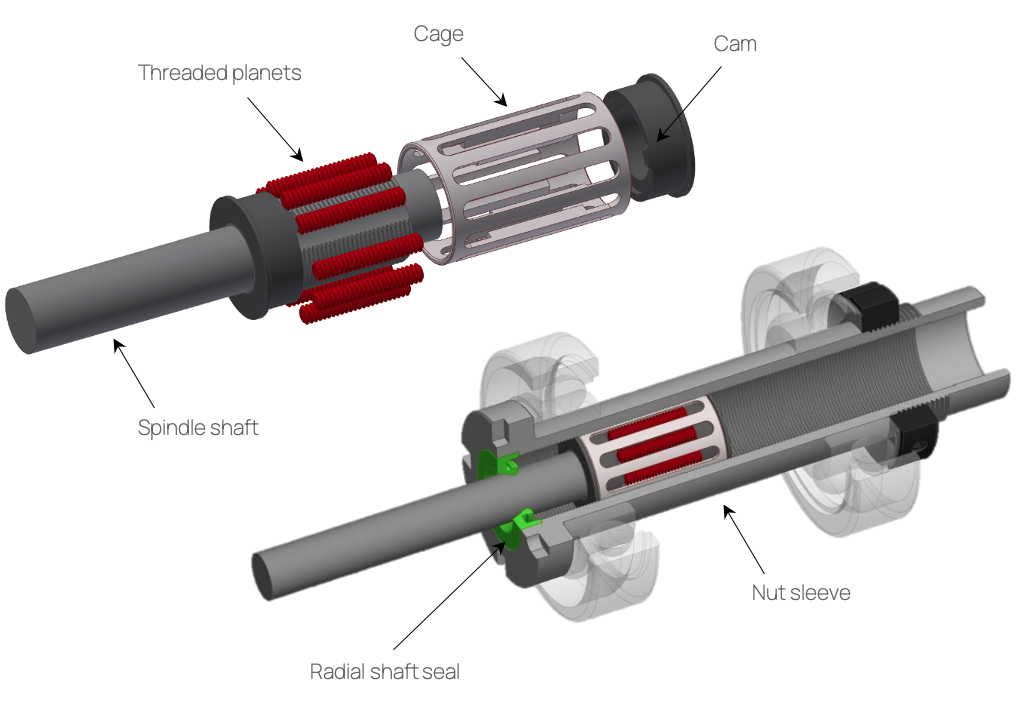

RGTI: Inverted Planetary Roller Screw

The RGTI with inverse design is an inverted version of the RGT. It has basically the same characteristics as the RGT and is also characterised by a high load capacity and positioning accuracy. In contrast to the RGT, in this design the threaded planets on the spindle are held in position and synchronised via the spacers and gears located on them. This inverse design has a smooth, cylindrical spindle shaft without a continuous thread profile. This allows the system to be sealed very well via the spindle shaft with a radial shaft seal.

Spindle nominal Ø: 10 mm to 60 mm

Leads: von 1 mm bis 30 mm

Dynamic load ratings: bis Cdyn 300 kN

Static load ratings: bis Cstat 650 kN

The RGTI is mainly integrated as an electromechanical drive in hollow shaft motors. It offers a compact electromechanical alternative to hydraulic and pneumatic lifting and linear drives. The threaded nut can be manufactured according to customer-specific design, depending on the nominal diameter, with a thread length of up to max. 800mm.

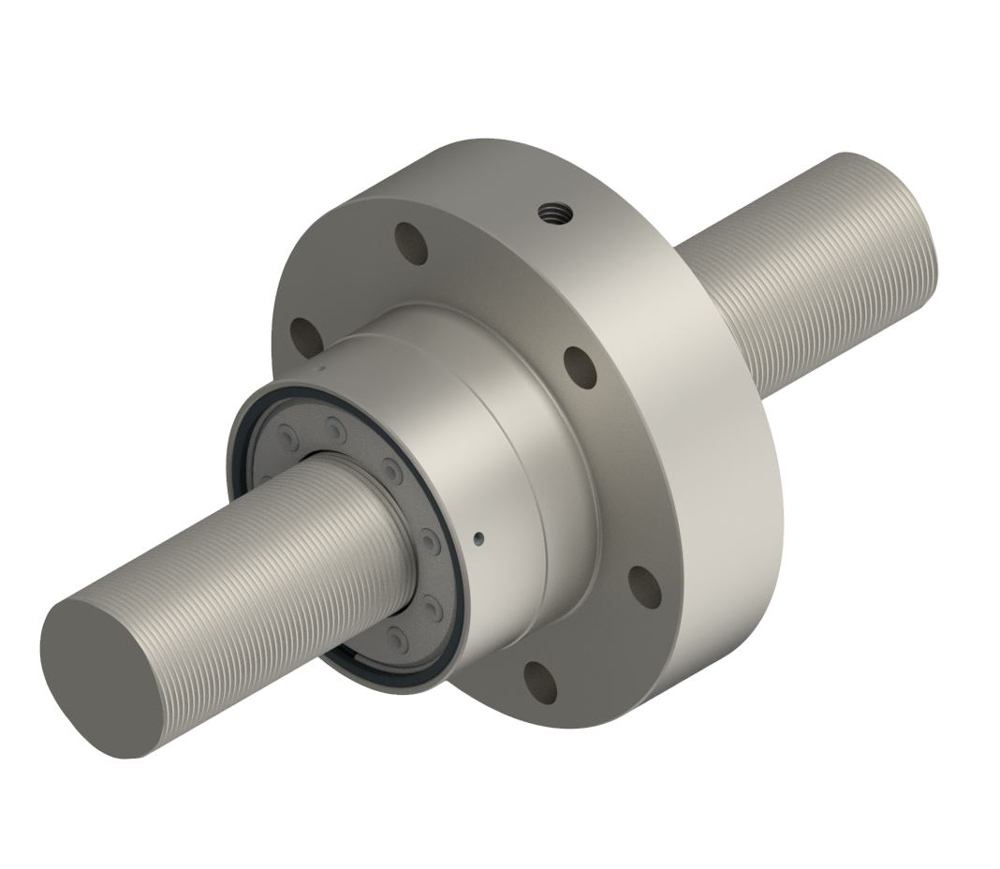

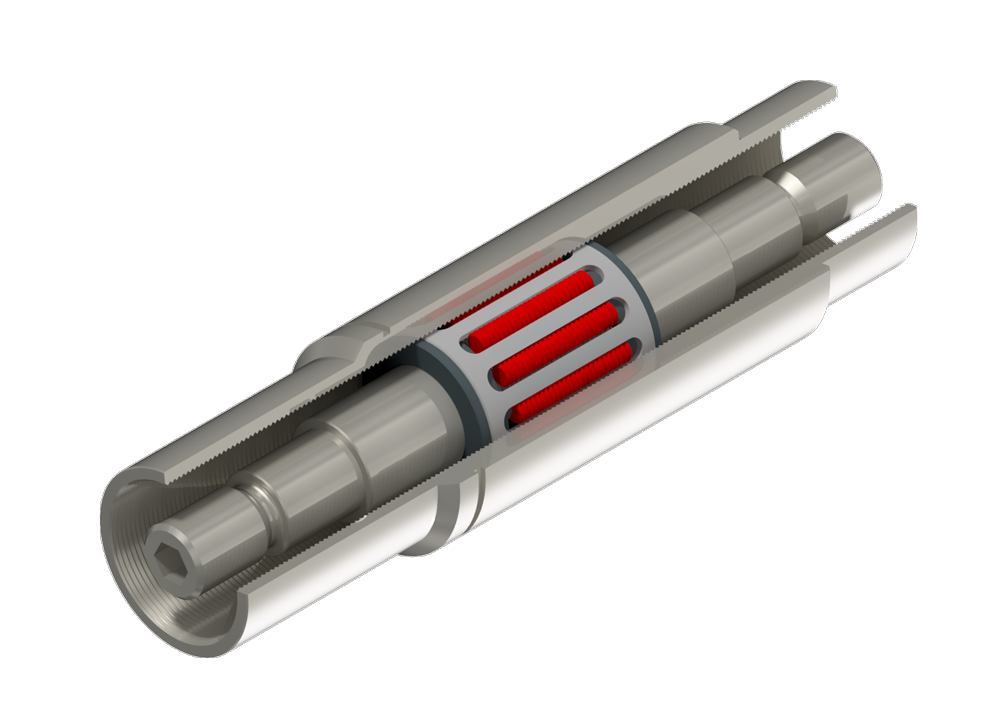

RGTRI: Inverted Recirculating Planetary Roller Screw

The RGTRI is an inverted design of the RGTR. The only difference compared to the RGTR lies in with the thread rolls cage as well as the recess for recirculating the thread rolls being located on the spindle rather than in the threaded nut. Thanks to the functional principle of recirculating rollers, the RGTRI is also characterized by small leads and more robust thread profiles at the same time. The smooth, cylindrical spindle shaft is also suitable for sealing the system in this inverted design.

Spindle nominal Ø: 10 mm to 60 mm

Leads: 0.3 mm to 5 mm

Load capacities: up to Cdyn 140 kN / up to Cstat 380 -kN

The RGTRI is also mainly integrated as an electromechanical drive in hollow shaft motors. This makes it a compact electromechanical alternative to hydraulic and pneumatic lifting and linear drives. Depending on the nominal diameter, the threaded nuts can be manufactured in customer-specific designs with a thread length of up to max. 800 mm.

We are responsible for this product.

Feel free to contact us if you have any questions:

Gewinde Satelliten Antriebe AG

Baselstrasse 5

4532 Feldbrunnen